|

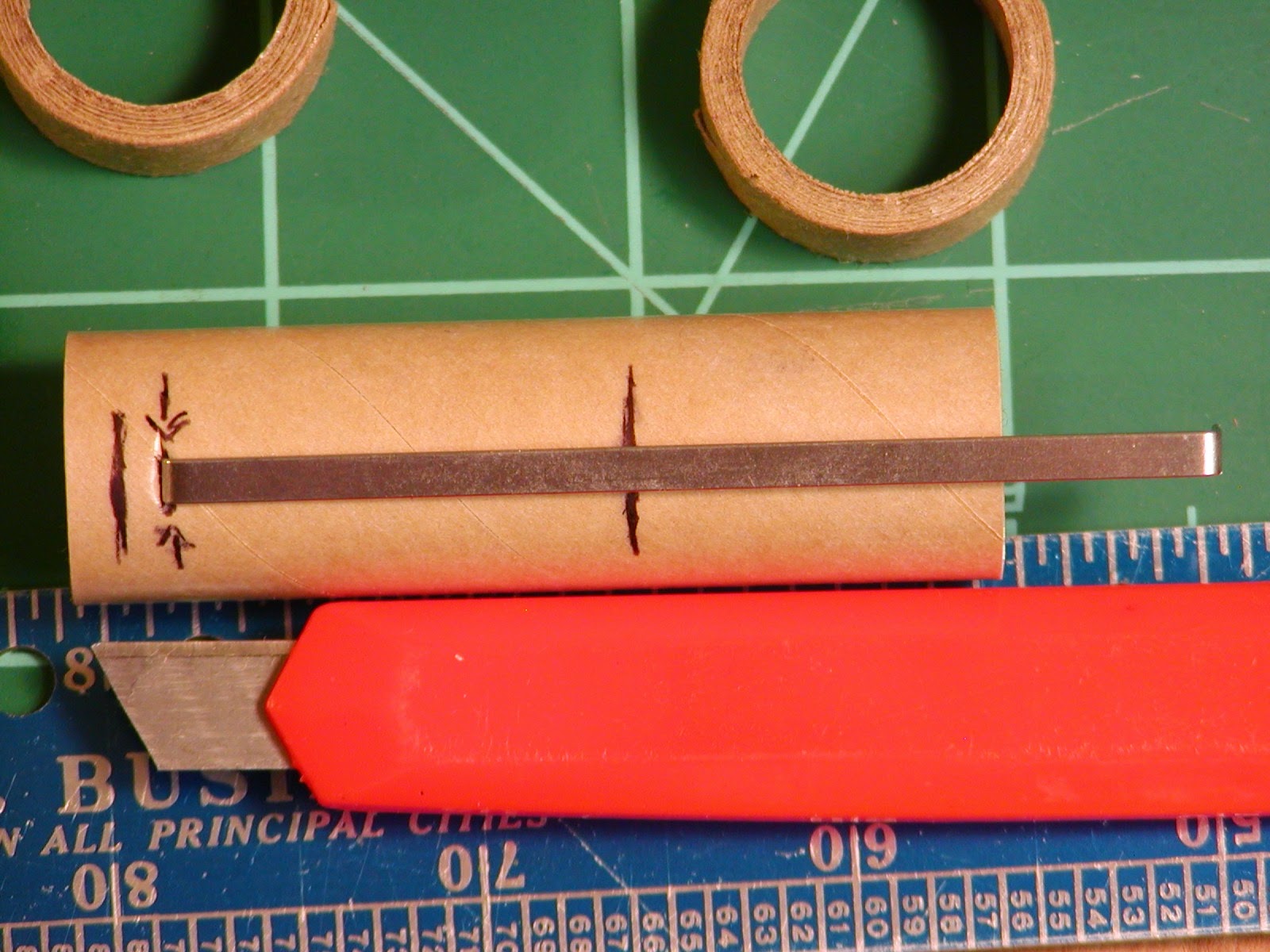

The original plans for the Renger Sky Slash II

Courtesy Estes & Jim Z's Rocket Plans |

Saturday, March 1st, 1980 dawned crisp and clear. The temperatures outside were nice, typical late winter in northeast Florida. For me, it was an extremely important day.

My Catholic Youth Organization chapter was having a "kite day" in the field next to the Sandalwood neighborhood. I wouldn't be flying kites that day, however. My model rocket club, the United Star Fleet (USF) would be putting on a demonstration launch. We had launched from this field dozens of times, and during all seasons. This would also be the first competition we would have.

We weren't an officially sanctioned NAR (National Association of Rocketry) chapter. Instead, we were a group of friends who loved rocketry and space travel. There were six of us initially that day including myself. My friends Alan Hastings, Joe Massal, the Horne brothers, Lance and Steve, and their father Gene, were there that morning. Shortly after arriving, though, the elder Mr. Horne had to leave, so in the end it was just the five of us. I was the club "president", as well as its founder. There were no formal rules. We built, and we flew.

This time, though, there would be that competition, with an emphasis on gliding time aloft. Four of the members had built Renger Sky Slashes II's. This design was one of the first successful boost gliders. The design, by Larry Renger, dated to May of 1963. One of my neighbors had been into model rocketry early on, but was now in college, so he gave me quite a bit of material from those early days. This plan was in one of those early publications, and was quickly passed around and copied by the members of the USF. I didn't have the time to build my Sky Slash II, but I did look on in envy at the slick looking gliders that Joe, Alan, and the Horne boys had built. Joe's was the most distinctive. It was overall gloss red with black trim and German Iron Crosses. The other gliders were more workman like in appearance, variously painted yellow, white and blue. Steve's was the only one that looked almost as daring as Joe's, being primarily golden yellow with dark blue trim, Sandalwood Jr. & Sr. High's colors.

|

The Sky Slash II flying surface patterns.

Courtesy Estes & Jim Z's Rocket Plans |

By 11 A.M. that morning, we had our three launch pads lined up. A steady wind came from southeast, not strong but still brisk enough. This made us set up in the field behind an old two story boarding house on the southeastern corner of the field at Mindanao and Bahia Drives. We weren't allowed to use their parking lot, so we went further into the field. Lance and Alan had cars. For Lance, it was an old compact station wagon. Alan, on the other hand, showed up in a real classic, a Studebaker President, that belonged to his father. Joe and I arrived on bikes. For me, it really wasn't that much of a ride, since I only lived a few blocks away.

|

The field at the edge of the Sandalwood neighborhood,

the way it looked on March 1st, 1980.

The dot is where we launched |

The first rocket to go up was going to be Joe's "Red Baron" Sky Slash. I don't remember why it was chosen, but believe it had to do with a coin toss. He took little time to prep the rocket, and soon it was sitting on one of our Estes Port-a-Pads.

Joe was the thriftiest amongst us, as well as the most daring. A short time before, he had purchased, in bulk, a box load of older Estes and Centuri model rocket engines from Art's Hobby Shop (our local hangout). Many of these engines dated back to the 1960's, and were prone to misfires and the occasional CATO (Catastrophe At Take Off). This didn't faze Joe, and for this, the first flight of his Red Baron, he had chosen an ancient Estes B series engine.

Once the glider was ready to go, we all participated in the standard five second countdown, and once zero was reached, Joe pressed the ignition button, and the red rocket glider shot skyward in a slightly backwards arching flight, with a very sparky engine providing the thrust. At about two hundred feet, the ejection charge kicked the engine out of the rocket glider, moving its center of gravity back to the wings and looping the glider. It then assumed a level, circling glide, and began following the wind deep into the field.

With Joe, Alan, Lance and Steve now involved with the recovery of the Red Baron in the waist tall golden meadow grass, I started back towards the launch pads.

As I approached, I noticed something.

There was a black disk in the grass that seemed to be radiating away from the Port-a-Pad. It was growing.

The grass was on fire.

It hadn't rained since mid-January. We had gone six weeks with barely any precipitation, and the grass in the field was extremely dry. By the time I spotted this expanding black disk, it was already over five feet in diameter. This burning disk was expanding with the wind, and moving towards the tall grass.

"We have a fire at the pads!" I shouted as loud as I could. Every head looked back in my direction, and soon the search for Joe's Red Baron was abandoned as everyone ran back to the launching area.

Next to the boarding house, two kids were playing. I shouted at them if we could use their water hose. Instead, they just stood up and watched. Alan and Steve took off their jackets and were batting the fire, which within a few minutes had scorched an area over fifty feet across.

It was heading towards the tall grass.

"We can't stop it!" someone yelled.

With that, it hit the tall meadow grass, and the field seemed to explode into an inferno.

Within minutes, two fire companies arrived and began laying down a parameter. They were more interested in keeping it from reaching the Pic-n-Save and the other strip mall at the corner of St. John's Bluff Road and Atlantic Boulevard. Nearby Craig Field diverted air traffic for a time, due to smoke drifting over the airport. Twenty minutes in, an Army National Guard UH-1D with a bucket appeared, out of nowhere, and dumped water on the western end of the field.

One of the saddest sights were the rabbits. Hundreds of them were running from the field, and it was breaking my heart. We had known that there was a warren in there for sometime, and I felt helpless as the scared animals ran from their homes and into the streets.

As a third company arrived, the weather began to change. Clouds began rolling in, and it looked as though we might just get some rain. But it wasn't soon enough.

Within an hour and a half, it was done.

The field was almost completely leveled. The few pine trees in the field still stood, their trunks blackened but otherwise unfazed. The cabbage palms, as well as a large number of wax myrtles, were damaged even more severely. The only portions of the field that were relatively untouched were the western third as well as the area near the eastern edge (next to the playground equipment that generally stood unused alongside Mindanao Drive, and where we normally launched). Where the launch pads had first stood was untouched, though the cars and equipment were moved when the inferno began. There was an area behind both the Pic-n-Save and the neighboring stores that was untouched as well; a fire company parked their trucks along that strip, and sprayed the area down solidly.

When it was all done, I walked resolutely into the field until I found the captain of the first fire company to arrive.

"Sir," I said, tears forming in my eyes, "my name is Robert Little, I'm president of the model rocket club. This was our fault. It was an accident. We didn't mean to start this fire, we've never had problems like this before."

He was a muscular man, with a really thick moustache. Judging from the salt and pepper in his hair, and his rugged looks, he had battled many blazes. I wasn't sure what was about to happen next.

Looking at me, he tilted his helmet back, looked around a couple of times, and then looked at me again.

"Son, we've been trying to have controlled burns here for months. Only got an acre or two done. By accident, you burnt the entire field down. We let it. All we did was to keep it contained." Then he laughed, "I should be thanking you!"

I nodded.

"Next time, you need to keep someone by your launch pads, maybe get a fire extinguisher. Got it?" he asked.

"Yes sir," I said. He took his glove off, extended his right hand, and gave mine a firm shake.

"Just don't let this happen again, okay?"

"Will do, sir."

That evening, a gentle rain fell over Jacksonville, and it grew colder. The next morning, the rain turned into snow, though it barely accumulated. As we left for church, we passed the now blackened field. Nobody in the car said a thing, but I still felt a pang in my heart for what had happened.

The following launches would never have a mishap of that magnitude. There would be CATO's, failed recoveries, launch clips snagging tails, and the occasional out of control bird. But there would always be one person standing guard at the launch pad, a fire extinguisher nearby when we could get one. It was a lesson that we learned the hard way.

Our luck was never that bad again.

|

The field the way it appears today. Since 1981, it was gradually

developed. Only the western half remains. |